I am able to pull a vacuum on my system, but when I blank-off, the micron gauge rises rapidly.

I am able to pull a vacuum on my system, but when I blank-off, the micron gauge rises rapidly.

Unless you are using JB`s DV-29, copper tubing, or flexible metal hoses, it is not recommended to use your existing manifold and hoses for blanking-off a system to check for leaks. Hoses work very well under high pressure. Vacuum is very critical in leaks, more so than pressure. All charging hoses, including the black hoses 1/4″ or 3/8″ permeate. Where the crimp is on the brass to the hose also has possible leak issues, and the gasket at the coupler is a major leak offender. The vacuum industry uses O-rings on most couplers. When you screw down on a gasket, it goes into many contortions and will not seal. When using an O-ring, you screw down on it to get a metal to metal seat and the O-ring lies around the lip of the flare giving it a positive seal.

question for vacuum pump and vacuum gauge

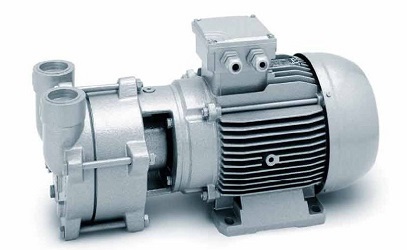

IMPORTANT- Always check the oil level with the vacuum pump running

Why do I need to check the oil level when the pump is running?

How low of a vacuum should we pull on a system?

Can I mount my micron gauge onto the vacuum pump?

I am able to pull a vacuum on my system, but when I blank-off, the micron gauge rises rapidly.